- Thermal efficient furnace chamber

- High purity graphite crucible machine to precision tolerance

- Equipped with the latest technology and design

- Multi-zone heating system for better heat curve accuracy

- Heavy Duty HR steel constructions with removable top

- Precision manufactured high density graphite casting dies

- High quality and durable silicone carbide heating element

- Wide range of casting applications to meet all our customer's requirements

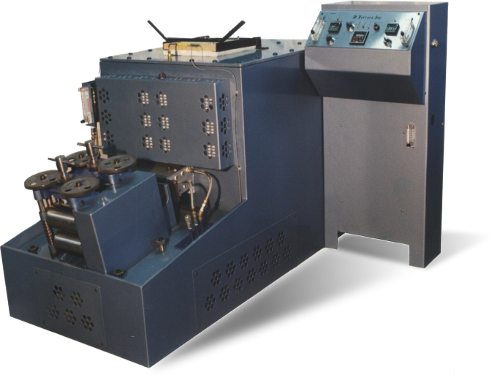

N. Ferrara Inc manufactures the most trouble-free Continuous Casting

Machine in operating and maintenance on the market. Its heavy duty

construction combined with our continuous effort in using the latest

technology makes the equipment free of problems, leaks, die and crucible

wear.

The continuous casting machine obtains a high flexibility for most

materials including copper and copper based alloys, gold, silver and all

precious metals. It operates under atmosphere inert gas which minimizes

the oxidation of graphite crucible and die. Its ability to recycle

scrap metal and precious metal makes it possible to cut costs and reduce

waste which allows for more profitable manufacturing for our customers.

We use the highest quality silicone carbide heating element to power

the heat zone. This enables a longer element life, a decreased cost in

replacing the elements less frequently and its unique design makes it is

easier to change the element (normal replacement time is 15 min with a

HOT Furnace).

- Continuous Casting

- Ingot Casting